This Division was established in 1953 in collaboration with German Firm M/S KSB to manufacture Centrifugal and Deep Well Turbines. In 1959 an agreement for technical collaboration with M/S Jaccuzi Bros. Inc. of USA was concluded for Deep Well and Submersible Turbine Pumps.

The division has complete testing facilities and qualified mechanical and hydraulic engineers.

Pumps division produces Centrifugal, Turbines and Submersible Pumps for various depth and discharge heads as per requirement of our valued customers. Pump line also include non clogging/industrial pumps of various capacities for sugar/ chemical industry.

Total components are being manufactured in house.

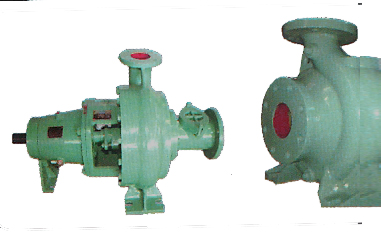

PECO CENTRIFUGAL PUMPS

INTRODUCTION

PECO Centrifugal Pumps have been designed by experienced and qualified designers keeping in view easy maintenance, maximum durability and highest reliability during their operation. These pumps are made from finest material with most modern manufacturing technique.

USES

Since PECO Centrifugal Pumps have wide range of pumping capacities, they can meet low , medium and high head demands of agriculture, construction drainage, sprinkler-water-irrigation and fire fighting. They are also suitable for various industrial plants.

PUMP CONSTRUCTION

Low and medium head pumps are single stage with end suctions and vane of volute type construction. For high heads, multistage diffuser vane type pumps are used. Main components of these pumps are:-

CASING

This is made of high grade cast iron. It is hydraulically tested under pressure before assembly. The discharge opening can be arranged in either 45° or 90° to the vertical position as per normal practice. The suctions and discharge openings are of flanged construction drilled according to British standard specifications. An effective stuffing box combined with a bronze bearing ring acts as chamber for sealing of liquid against leakage and prevents entrance of air in the pump.

IMPELLER

Single suction closed type impeller is made of fine grain cast iron. It is dynamically and hydraulically balanced and back-filled on vanes for vibration free running. It is keyed to the pump shaft and clamped by a lock nut. Cast Iron wear rings are fitted to the pump casing and the suction cover to prevent leakage. If required, bronze Impellers can also be supplied.

BEARING PEDESTAL

Heavy duty bearing pedestal made of high grade cast iron is flanged to the pump casting. The pump shaft is supported by two deep-groove ball bearing anchored in the pedestal. The shaft is made of high quality steel having big enough diameter to transmit safely the highest permissible torque. An oil reservoir built in the pedestal provides the lubricants to the bearings .End covers of the bearings are fitted with oil and dirt-proof seals

PUMPS MODELS AND DRIVES AVAILABLE:

Model PCO: Bare shaft pump:-

These are pedestal type pumps with no driving arrangement.

Model PCB: Pump with Fast Pulley:- This pump is fitted with a pulley of 200 mm diameter fixed to the shaft end .The pedestal and the shaft anchoring bearings are safely designed to take the necessary belt pull. No base plate is required. It is suitable for drive by high/slow speed diesel or through a line shaft with a belt speed of 50 ft. per sec.

Model PCF: Electric Pump:- This type consists of PECO-Newman motors connected to the pumps through a flexible coupling and mounted on a rigid cast iron based. Perfect alignment guarantees trouble free service. Electric motors are horizontal squirrel cage type,4 pole, AC 400 3/5 with nominal speed of 1460 and 2900 RPM.

Model PCE: Monoblock pump:- A sturdy bracket of cast iron with foundations holes carries the pump volute casing at one end and a flanged PECO-Newman motor on the other end. Pump and motor shaft are an integral part. The shaft is protected against wear and corrosion by a stainless steel sleeve. This type is lighter and requires less space than the PCF Model, but is equally sturdy and dependable. Motors are flanged squirrel cage type, 4 pole AC 400 3/50, with speed of 1460 RPM.

MODEL PCD: Diesel Engine Driven pump:- This type consists of PECO high speed diesel engines connected to the pumps through a flexible coupling and mounted on fabricated steel base plate. This type is also available as mobile pumping set with steel wheels, tow bar and retractable stays fitted to the base frame. Such a model is indicated by index “M”

Mobile pumping sets can also be provided with solid rubber or pneumatic tyre wheels for easy towing on special order. Pumping sets with GH-195 engine are detailed in a separate Leaflet.

PECO HORIZONTAL NON CLOGGING PUMPS

PECO Horizontal Non Clogging pumps (choke less) are suitably designed and experimentally developed to handle the wide variety of liquid -solid mixtures and for the viscous substances. They are robust, reliable and easily accessible for quick maintenance. All materials using modern production methods with strict quality control. interchange ability of parts is ensured

APPLICATIONS

SLUDGE & SEWAGE:

Crude rough screened sewage, storm water with sewage. industrial and chemical effluents, partially treated sewage, crude sludge and similar application

PAPER INDUSTRY:

Mixture of water cellulose and pulp.

SUGAR INDUSTRY:

Raw juice, mild of lime, lime juice, muddy juice, raw water, soda solution, hot syrup.

FOOD PROCESSING INDUSTRY:

All types of mixtures of water with vegetables, fruit, peeling, grains etc.

RIVER WATER:

For lift irrigation, settled storm water and canal/lake water.

CHEMICAL INDUSTRY:

All kinds of chemical fluids containing crystalline solids, vegetable oils soups ammonia

COMPONENTS OF THE PUMP

PUMP CASING:

Volute type pump casing with tangential discharge made of high grade cast iron, can also be supplied in nickel cast iron or bronze against special order, Casing in hydraulically pressure tested before assembly. An opening is provided on the upper side for impeller cleaning. The stuffing box is packed with graphite and lubricated hydraulic cotton packing which also suits Ammonia, brines and other fluids even at elevated temperatures.

Stuffing box can be supplied with mechanical seal on request. Wear rings are fitted in the pump casing to prevent leakage.

SUCTION COVER:

A large opening is provided in the suction cover for the easy removal of suspended matter clogged at impeller inlet.

IMPELLER:

Single suction closed type impeller of fine grain cast iron is supplied as standard impeller for pumping sewage water where as Impeller stain less steel or nickel cast iron is supplied against specific order. Impeller is statically and dynamically balanced and back filled on vanes for vibration free running. The vanes are robust and have well rounded inlet edges to prevent entangling of rags or stings.

BEARING PEDESTAL:

Heavy duty bearing pedestal of high grade cast iron is connected to the pump casing through adopter. The pump shaft is supported in two widely spaced large size Deep-groove Ball Bearing fitted in the pedestal. The shaft is made of high grade carbon steel for pumping sewage water, where as stainless steel shaft is supplied against specific order.

The shaft is capable of safely transmitting the heavy torque. A bronze sleeve is fitted under gland packing in the bush bearing. An oil reservoir built in the pedestal keeps the bearing lubricated. End covers of the bearings are fitted with oil and dirt-proof seals.

COUPLING:

Pump and motor are coupled through flexible / universal type couplings

DRIVE:

PECO pumps are driven by means of a horizontal electric motor or diesel engine through a flexible /universal coupling mounted on a rigid fabricated base frame. Perfect alignment guarantees trouble free service.

PECO DEEPWELL TURBINE PUMPS

INTRODUCTION

PECO deepwell turbine pumps have been expertly designed keeping in view the requirement of our customers for easy maintenance, maximum durability and highest reliability .The components of these pumps are made from the finest material on the most modern manufacturing machinery with the highest precision and accuracy to ensure the best operational life.

Because of strict quality control at all stages, PECO deepwell turbine pumps are un matched in quality and performance at minimum operational cost. These pumps are available in various capacities to meet specific needs of the clients. They are meant for deep installation in narrow bores ranging 6” to 16”.

USES

PECO deepwell turbine pumps are ideally suited for irrigation, water treatments plants, and special projects such as salinity control, waterlogging, water pumping, boosting of water heads etc.

SALIENT FEATURES

Some of the distinct features of PECO deepwell turbine pumps are as follows.

- Their Bowl Assembly and Impeller have mixed flow design for optimum pump efficiency

- Their pump shaft is made of stainless steel and ground finished , for perfect alignment and longer bearing life

- All rotating parts are dynamically balanced to ensure smooth operation with minimum vibration.

- Suction stage bearing is grease-packed for life

- Easy and cheaper maintenance is assured due to abundant and country wide availability of spares and repair facilities.

- Every pump is 100% inspected and tested before delivery.

- Backing of after sale service by highly qualified and experienced engineers and staff is available.

MAIN COMPONENTS OF DWT

Deepwell turbine pump comprises following main components.

BOWL ASSEMBLY

Bowl assembly is the main pumping element and essentially consists of the requisite number of bowls and impellers (Commercially called stages ) Bowl assembly has flanged ends to receive suction bearing stage. The closed type bronze impellers are designed and finished for highest hydraulic efficiency. They are also dynamically balanced to ensure smooth and vibration free running.

Sand caps are fixed on pump shaft for protection and longer life of the bronze bearings.

The suction stage bearing is grease-packed for life.

The discharge stage bearing is water or oil lubricated with corresponding types of turbine pump.

Column and Head Assembly

In PECO turbine pumps ,the bowl assembly is suspended by means of an assembly of column pipes connected to the discharge head. The column assembly comprises three components, namely the line shaft, bearing and column pipe. The dimensions of column pipes are designed to provide complete stability to the entire pump. It also acts as a water discharge pipe. Only PECO offers water and oil lubricated versions of column and head assembly for these pumps.

WATER LUBRICATED

The line shaft in the water lubricated turbine pump is supported at10 feet intervals by fluted rubber bearings inserted in the integrally cast boss retainer of the socket coupling,

Which is threaded to receive the column pipes. This ensures prefect concentricity and alignment. At each line shaft bearing, a stainless steel shaft sleeve provides a non-corrosive bearing surface. Since the shaft sleeve is threaded on to the line shaft and locked In place by the line shaft coupling. It is easily replaceable in the field. The surface type discharge head is fitted with the cast iron stuffing box with removable bronze bearing and follower which is grease-packed to avoid seizure during operation.it also ensures long-life of the head shaft.

DRIVE SYSTEMS

PECO deepwell turbine pumps can be supplied with one of the following drive systems:-

MOTOR DRIVE

PECO deepwell turbine pumps are normally supplied with PECO NEWMAN vertical hollow shaft electric motors as standard equipment. These motors are completely weather protected in accordance with NEMA standards.

GEAR DRIVE

In gear drive system, PECO turbine pumps are driven by standard right angle gear drive heads connected to diesel engine through a close coupling. These gear heads accommodate prime movers with different speed ratios to suit both the prime movers and the turbine pump.

COMBINATION DRIVE

Combination of an electric motor and a right angle gear drive head is useful when auxiliary power is required to provide un-interrupted service in the event of electric power failure. The mechanism is designed in such a way that each drive can be switched over independently thereby disengaging the unwanted drive.

A multi-disc frictional clutch is provided to cut off the diesel engine drive when the turbine pump is operating with motor.

FLAT BELT DRIVE

PECO flat belt drive heads permit operation of the turbine pump by means of electric motor, diesel engine and tractor power take-off through quarter turn belt arrangement.

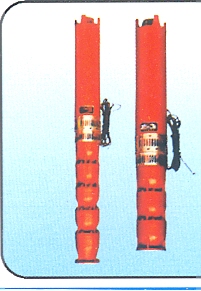

SUBMERSIBLE PUMPS

APPLICATIONS

PECO Submersible pumps are used for water supply from borehole of deepwells for agricultural purposes such as tubewell installation of cities and rural areas for industry service water supply installation and a great variety of other purposes including air-conditioning system.

These pumps can also be used as booster pumps, ground water levels in mines.

Advantages

- Since column shaft, shaft couplings and guide bearings are eliminated these pumps have comparatively low initial cost particularly for deeper setting and low noise level.

- They involve no suction problems and also require no pumps house or other civil work as they are installed below the water level.

- These pumps are built to operate in the well submersed in water and require minimum attemtion.

- Beside they give overall higher efficiency needing very little maintenance and no lubrication.

- They can be easily installed in crooked wells.

- They are very economical in operation.

- The pump operates out of sight.