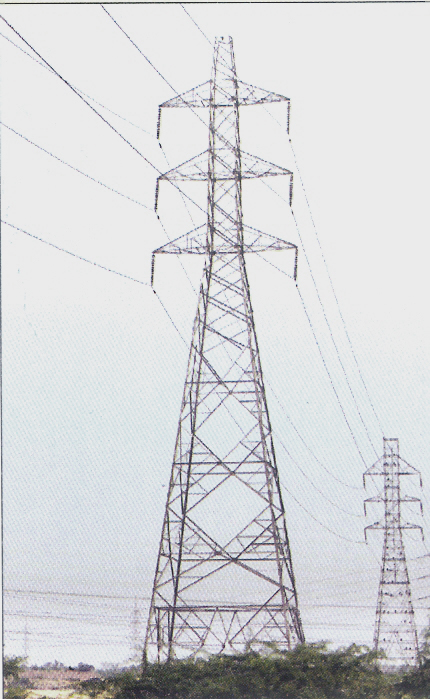

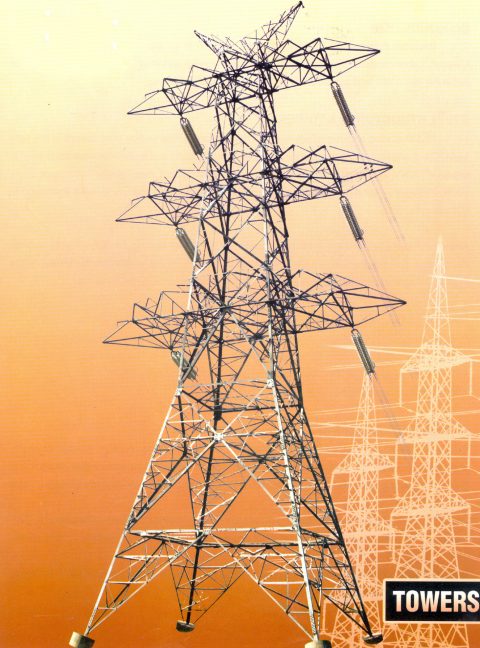

PECO started manufacturing electricity Transmission Line Tower in 1964. The Company has the advantage of having all in-house facilities for production of tower i.e. steel re rolling, fabrication, galvanizing, designing and testing. No other company in Pakistan has complete range of in-house facilities for production of transmission line towers under one roof. Our present product line consists of 11Kv, 132Kv, 220 Kv and 500Kv transmission line towers. PECO is the only Company in Pakistan to make 500kv single and double circuit towers.

ISO 9001 CERTIFICATION:

PECO got ISO-9001 certification in August 1999. The scope of present ISO 9001:2015 includes Designing, Manufacturing, Erection and Exporters of all types of general structure transmission line and telecom towers, Electric Motors, Pumps and Casting parts.

The Certificate is renewed till 2017.

DESIGN AND ENGINEERING:

PECO has in house computer aided design and drafting facilities. Highly experienced design engineers and drafting personnel are engaged for economical designing of Electricity Transmission Line Towers and Switch Yard Structures for any level of voltage between 11Kv to 500Kv.

PECO also has design facilities for Microwave Guy Rope Antennas, Telecommunication Towers, Self Supported Towers and a large variety of steel structure such as gantries, factory sheds etc.

PECO has also arrangements with reputed international organizations for designing and testing of prototype towers before manufacturing.

STEEL RE ROLLING:

Four semi automatic Re rolling mills installed at our works can produce rolled products like Equal Angels, Channels Deformed Bars of various sizes and Grades. These Mills can produce annually up to 30,000 tons of steel sections. Maximum steel angle size 150 mm can be rolled in house.

TOWER FABRICATION:

State of the art ,Italian CNC machines alingwith Iron Workers are used for accurate punching , cutting and stamping of tower members . PECO`s manufactured towers have been tested for loading and field conditions at renowned testing stations in Europe and China .

PECO is the largest supplier of Transmission Line Tower to NTDC and different DISCOS in Pakistan. PECO tower capacity is 20,000 tons per anum. It ranks among the largest manufacturers of this product in South Asia.

GALVANIZING:

There are three different hot dip galvanizing plants where all operations of pickling, cleaning and hot dip galvanizing are carried out in a systematic way to ensure smooth and even layer of zinc deposit of required thickness .Tower members are inspected individually and in batches for defect free galvanizing and a layer of uniform thickness prior to shifting to storage yard. Tower members are stored in a vast area in a well planed way to ensure smooth unloading and loading.

QUALITY CONTROL:

Quality is ensured according to internationals standards. Samples of steel angle sections are further tested for mechanical, chemical and bending properties prior to fabrications scientifically, both for prototype development and commercial production. All members are individually checked to detect any fault in galvanizing .Similarly sample check of zinc layer thickness is conducted regularly.

TESTING FACILITIES:

PECO has modern material testing laboratories equipped with latest and sophisticated equipment to provide quick and reliable material testing analysis during steel making. These testing facilities ensure correct material specifications both chemical and mechanical. Some are listed below:-

- LECO`s Carbon Sulphur Determinator.

- 100 ton`s Universal Testing Machine

- Combustion Analyzer

- Complete Metallography laboratory including :-

- Microscopy X-1500 magnification

- Ultra Sonic Flaw Detector

- Magnetic Tester- Brinell and Rockwell